We offer comprehensive engineering services for your printing presses.

We are happy to assist you in the following:

- to keep your printing press running smoothly

- To ensure the electronics (controllers) are state of the art

We are your partner for maximum utilisation of your printing presses with the highest possible output.

Engineering for Print

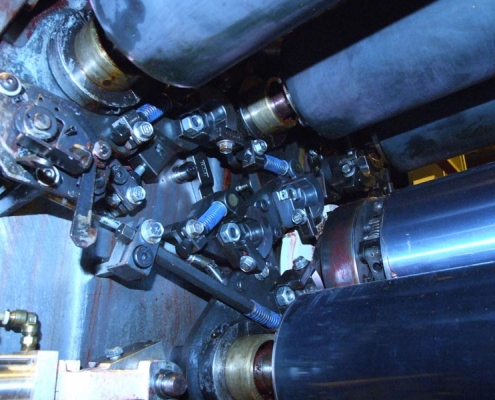

Folder belt service and optimization

Especially for the high volume machines, the folder belt service is a very important factor for a stable production between the maintenance intervals.

We take care for optimum product transport from the folder to the stacker

- correct material selection

- optimal band preparation

- optimized adhesive / band processing technology

- Adjustment and service of the mechanical components of the transport route

- well-trained and experienced technicians

High Quality Service Printing Presses

from Machine Guru

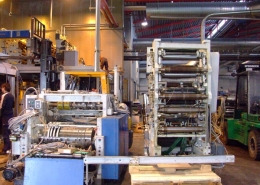

From the necessary replacement of wear and tear parts several times a year to the intensive annual overhaul, we offer you the solutions tailored specifically to your needs.

Thanks to our many years of experience with the most widely used machine types from MANROLAND KBA and GOSS, we are well aware of their advantages as well as their weak points. We are your partner for maximum efficiency with the highest possible output for your printing presses.

Our service includes

- Workflow management

- Spare Parts Management

- Support your technicians or carry out the necessary service work alone

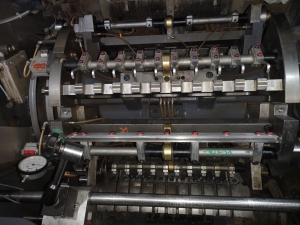

Service printing units

- Dry Ice cleaning

- Roll exchange

- Ink fountain inspection

- Bearer ring control with (where necessary) cylinder bearing exchange

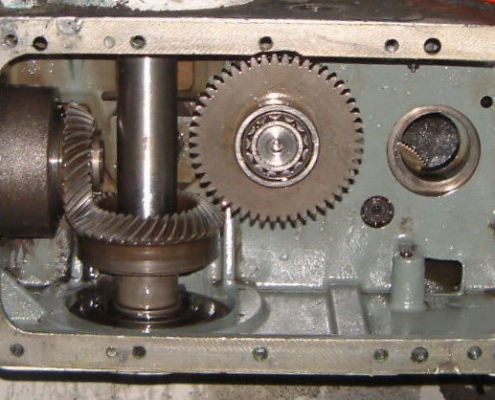

Service folder

- Service on the cylinders of the base unit

- Timing belt replacement

- Checking and adjusting the gear train

- Service at the chopper fold (second longitudinal folder)

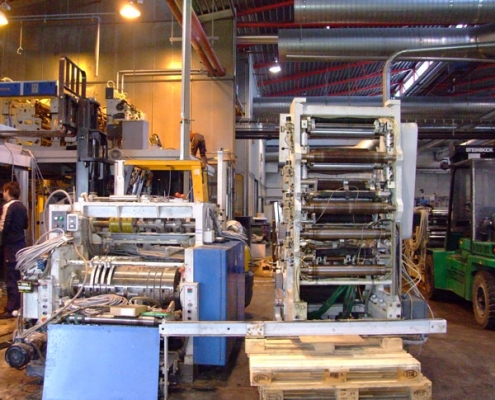

Machine relocations / transfer

Be it internal machine relocation or relocation of entire production lines to other locations – we are happy to support you in this challenge, from planning to commissioning.

Under our guidance, we have already relocated the following facilities:

- Harris M1000 in parallel setup of two lines for 2 x 16 Pages oder 1 x 32 Pages

- Heidelberg M600

- Lithoman IV – 64

- Compacta C-214

- Compacta C-618

- various Saddle-binder – Müller Martini

- Pallet wrapping Equipment – Mosca

We look after

Printing machines and controllers of these and many other manufacturers