Our custom machine design & construction ranges from small detailed solutions such as conversions or additions to existing units (web offset presses / commercial presses) to the production of standalone systems. Above all, we have extensive experience on older systems and ensure that the electronics remain state of the art (retrofit).

We have already developed the following customised projects:

Cutter for attachment to an Octoman

The two-former unit was designed to process the feed of an 8-page web offset press to produce products 4×4, 2×6, 2×8 pages between 45 and 180g / m².

Our work included

- the design of the entire system as well as the individual components

- the manufacture and assembly

- as well as the assembly and commissioning.

The production speed is 50.000 rev / h.

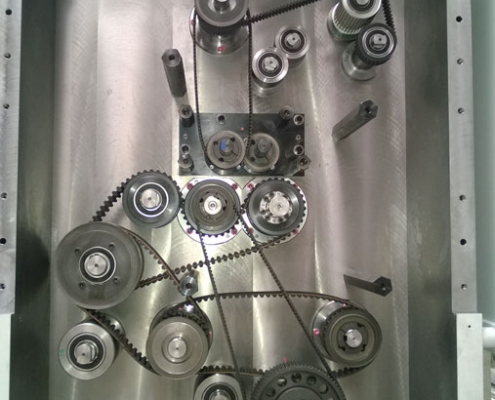

The drive is via a virtual line shaft.

Angle bars after the former of a Polyman

Conversion at the customer’s wish to be more flexible at the ribbon stitcher.

Our work included

- the design

- Production and

- Installation of a double angle-bar deck, which after the funnel gives the customer the opportunity to adjust the feed to the folder entry by 180°.

Lifting straps on folder PFW5 of a Lithoman IV-48

Conversion on customer request, to avoid the problems (marking and paper jams) by guide to the folding jaws.

Our work included

- the design

- Production and

- Assembly of the components.

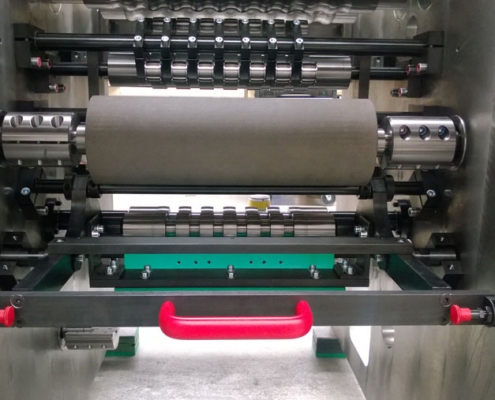

Expiring reel unwinder

to obtain the white paper waste from the reel core for web widths of 500 – 1800mm

Retrofit of machine control

In cooperation with our customer ABB we have already realised several retrofits.